4 min read

Converting a Manual Screwdriving Solution Into an Automated Screwdriving Operation

By: Carey Dupuy Sep 20, 2022 8:30:00 AM

First things first, converting a manual screwdriving solution into an automated screwdriving operation isn’t as easy as you may think. When you have operators manually driving screws into assemblies, you may not realize exactly what error detection and fault correction abilities they are bringing to the process. Relinquishing these operators from the process to establish a quality automated alternative isn’t as simple as slapping a robot with a screwdriver end-of-arm tool into the workcell.

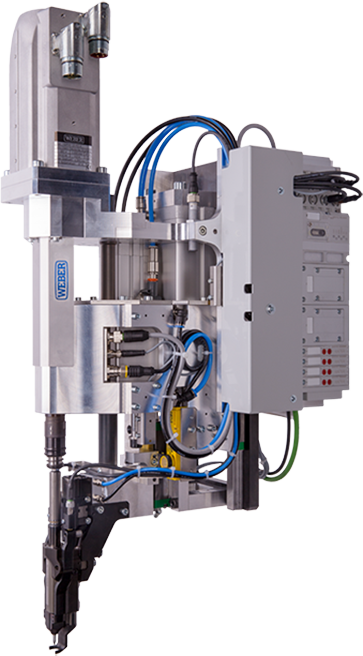

The entire assembly process may require a rethink or redesign of the parts, the pallets, the fastening techniques, and the error-proofing capabilities required in the operation. WEBER often has to break the news to customers that what they thought would be a simple conversion project is much wider in scope than they initially anticipated. Nevertheless, just because it’s hard doesn’t mean it’s impossible. Here are some tips to keep in mind when you want to convert a manual screwdriving operation into an automated screwdriving workcell.

The entire assembly process may require a rethink or redesign of the parts, the pallets, the fastening techniques, and the error-proofing capabilities required in the operation. WEBER often has to break the news to customers that what they thought would be a simple conversion project is much wider in scope than they initially anticipated. Nevertheless, just because it’s hard doesn’t mean it’s impossible. Here are some tips to keep in mind when you want to convert a manual screwdriving operation into an automated screwdriving workcell.

Uncovering the True Scope of Work for an Automated Screwdriving Operation

If you didn’t consider automation from the get-go, you’ll have to start the conversion project with a review of every element used in the assembly process. If you have a big plastic assembly like dashboard parts, operators would likely manipulate the parts manually to fit properly before completing the driving operation. Once there is no operator involved, these peripheral actions will have to form part of the automated screwdriving process. Therefore, understanding the true scope of the operation will extend beyond just the action of feeding, positioning, and driving the screw into the part.

Before you start designing the automated screwdriving workcell, you need to take a step back and consider:

- How does the robot move during the process while parts are entering and exiting the station?

- What is the intended path of the robot and screwdriver on the automated line?

- Where will you need additional fixtures to align the parts and hold them in place?

- What are the operators currently doing to ensure they seat each screw properly and according to specification?

If you know what these constraints and product liability issues are, we can start designing a system using our modular screwdriving solutions and process controllers.

How WEBER Approaches Automation for Screwdriving Operations

WEBER makes automation easy! We take a thoughtful approach by viewing the entire process from a holistic perspective. Vision systems can help locate the holes for each assembly but they increase cycle times. For improved Overall Equipment Effectiveness (OEE), we may have to rethink the part’s tolerances and dimensions by redesigning portions of the line for better manufacturability. This redesign may extend to the pallet system, the fixturing used on the assembly line, and what process control you can deploy to reduce product liability issues.

WEBER makes automation easy! We take a thoughtful approach by viewing the entire process from a holistic perspective. Vision systems can help locate the holes for each assembly but they increase cycle times. For improved Overall Equipment Effectiveness (OEE), we may have to rethink the part’s tolerances and dimensions by redesigning portions of the line for better manufacturability. This redesign may extend to the pallet system, the fixturing used on the assembly line, and what process control you can deploy to reduce product liability issues.

From our perspective, the sooner you engage with our experts the smoother the conversion to automated screwdriving will be.

We can advise you on:

- Ensuring the pallets are automation friendly

- How to redesign the fixtures for improved stability

- What process controller can help you error-proof the assembly operation

- Where tolerances and clearances need to increase to accommodate the automated screwdriver

- Finally, what the best configuration of feed technology, automated screwdrivers, and process controllers you’ll need to make sure you get the ROI you expect from the project

Shortening the Runway from Manual to Automated Screwdriving Operations with WEBER

With labor shortages hampering manufacturers, the journey from manual to automated screwdriving operations will become an inevitable reality for many companies. Ensuring you get it right the first time requires input from the experts before you scope the project and allocate a budget or worse, start ordering equipment and systems. WEBER can assist you to avoid the pitfalls from the beginning and ensure you understand the actual scope required and can succeed in bringing screwdriving automation to your challenging assemblies.

For more information about how we can help you convert a manual screwdriving operation to an automated screwdriving workcell, reach out to WEBER today.