System Solutions

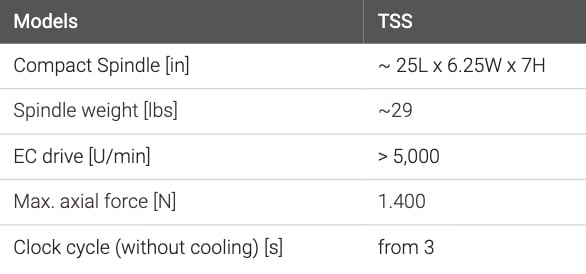

Thermal Setting System for Multi-Layer Structures TSS

Thermal adhesive bond

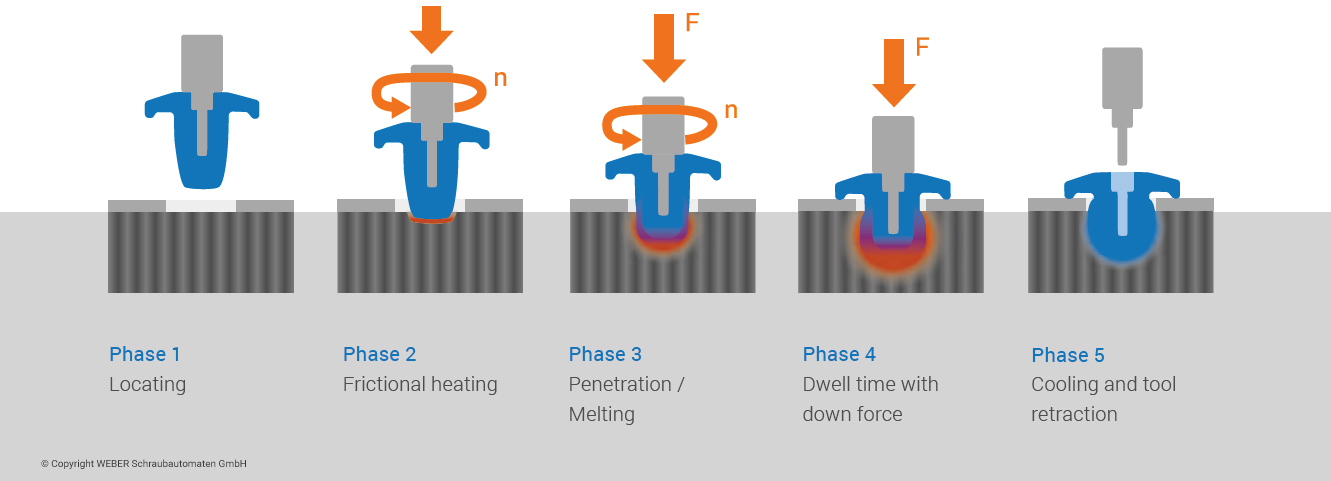

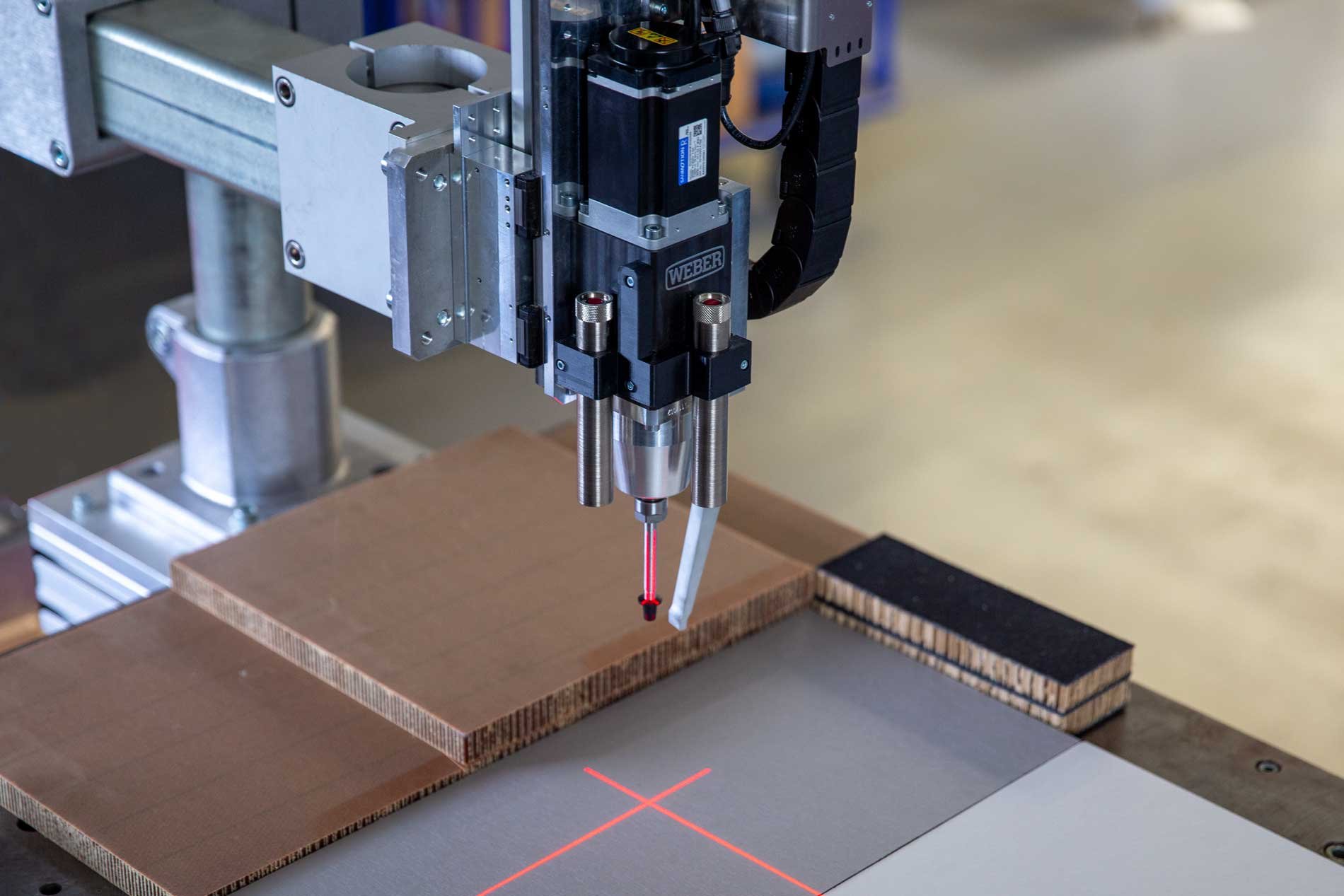

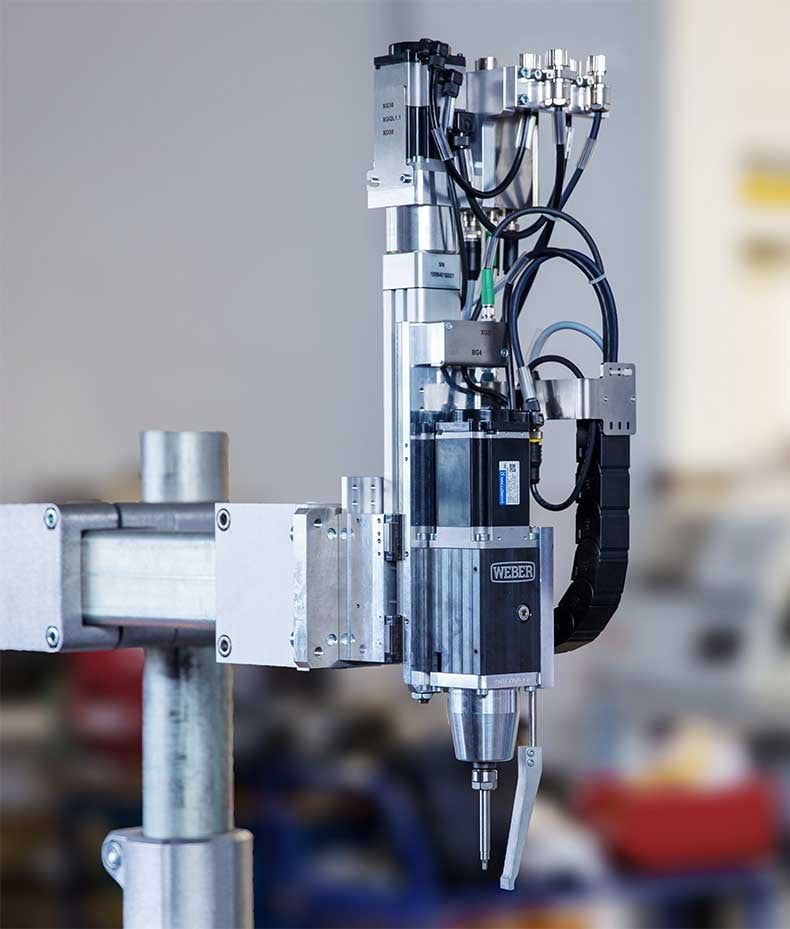

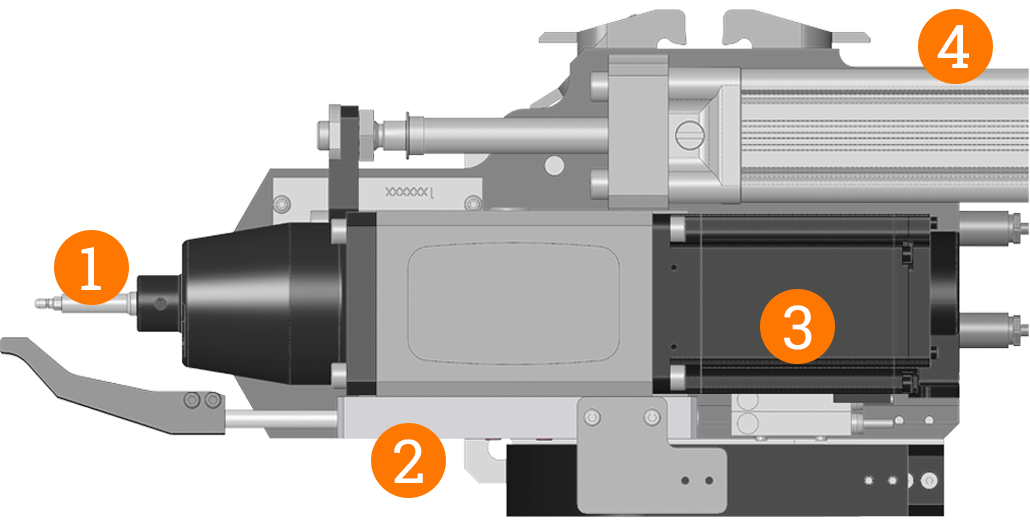

Following the trend to lightweight construction, breaking new ground in connection technology is essential. The TSS system allows placing of plastic bosses in sandwich structures, which consist of a honeycomb or foam core with outer layers of fiber-reinforced plastics (e.g., CRP or GRP). During the TSS joining process, the plastic components are melted, creating a thermal adhesive bond. Placing the plastic bosses is carried out with or without a pilot hole and can be implemented with robotic assistance.

Individual parameters

The TSS process is applied as a robot-assisted system, a closed setting facility in a cell or using a handheld unit. Domes are used directly as fasteners or robust threaded inserts for self-tapping screws. The entire process is freely configurable and can be documented.

Features

• Joining process for lightweight materials

• With and without pilot hole

• Initial assessment of materials to be joined in WEBER’s in-house laboratory