Screwdriving Technology for the

Woodworking Industry

Screwdriving Technology for Woodworking

In many sectors today, wood, particle board, MDF, composites, laminates, or other engineered wood products are processed industrially in large numbers and in varying quality depending upon source. Related assembly tasks are to be solved in various materials, for example, in window construction, furniture production or manufacturing of semi-finished wood products. The utilization of these various materials usually involves a refinement of raw material and standardized attachment hardware.

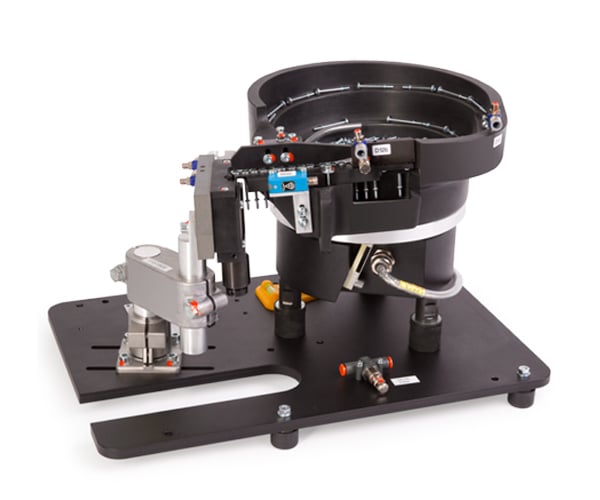

The wood industry places less complex requirements on automated screw assembly. The systems should be, above all, cost-effective to procure due to modular design and simpler component design. It is to be noted that wood is a natural material and as such, WEBER automatic screwdriving systems are designed to work in wider tolerance limits due to the variations in hardness, natural knots, water content, etc.

WEBER meets the high quality standards of our woodworking industry clients by providing consistently high-performance screwdriving technology. For example, WEBER’s handheld screwdrivers are typically used for mounting fittings, hinges, and other hardware in many window & door applications which enables precise and fatigue-free production even at high assembly volumes.