System Solutions

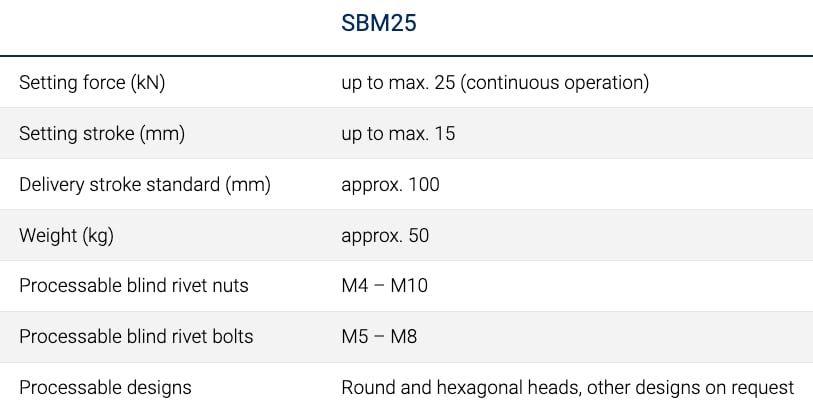

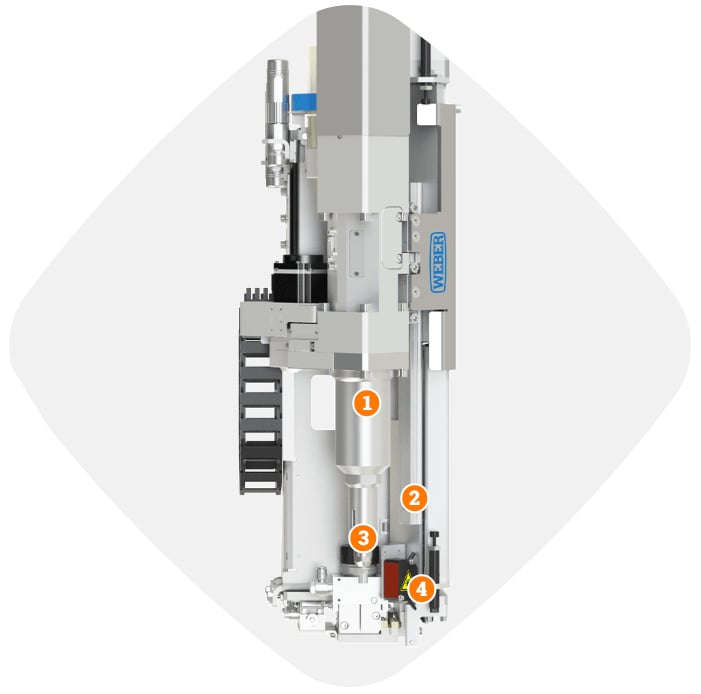

Setting System for Blind Rivet Nuts and Bolts SBM25

Blind rivet nuts. Efficient. Innovative.

Precision in every process step – for long-lasting connections!

Rely on process reliability with detachable connections in all positions.

Process-reliable automation for blind rivet nuts

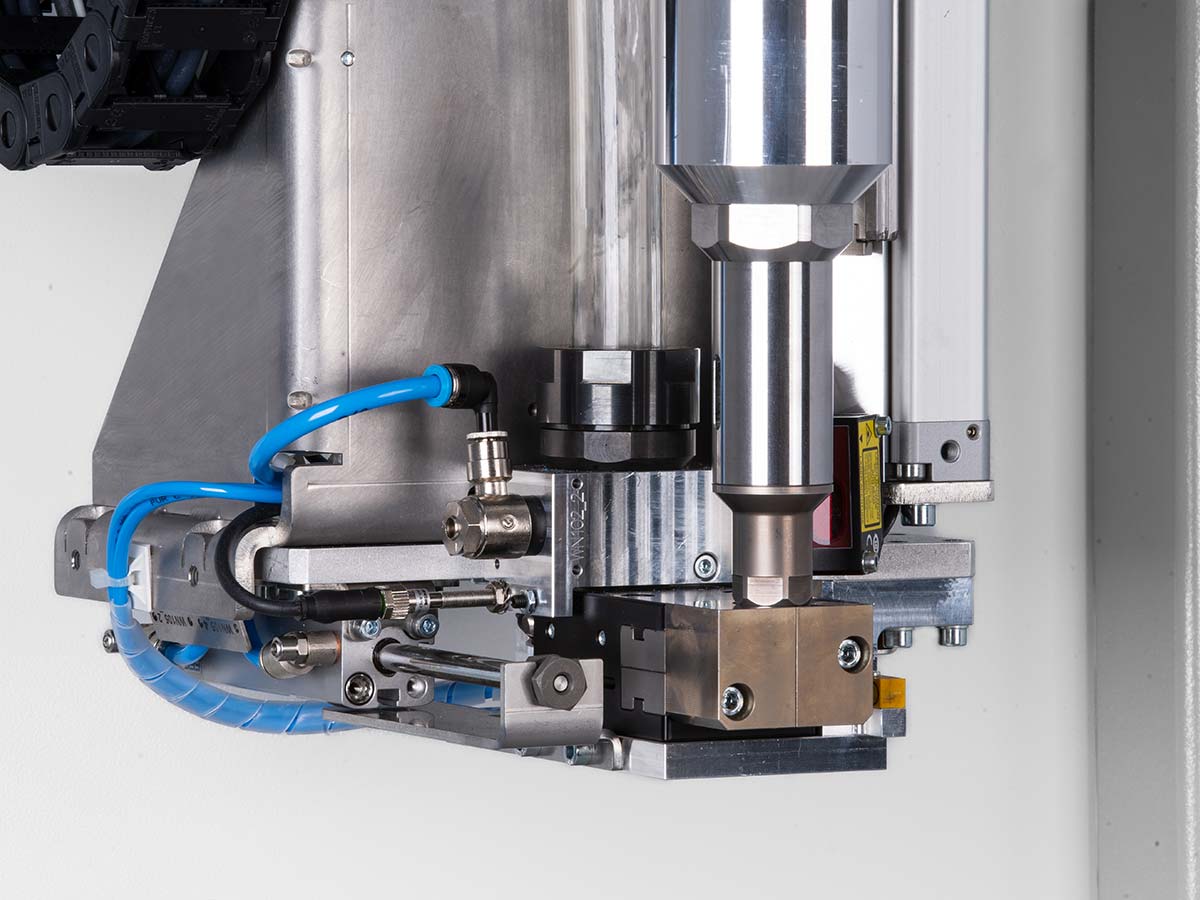

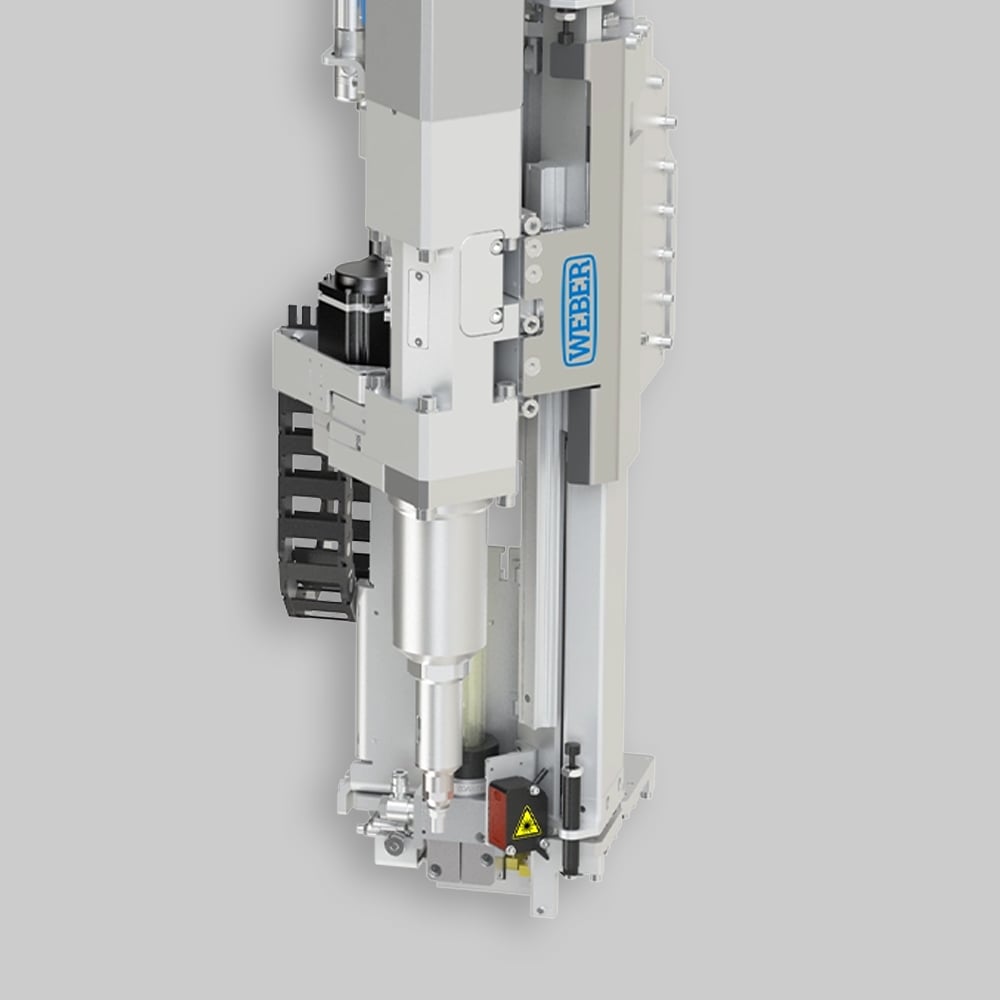

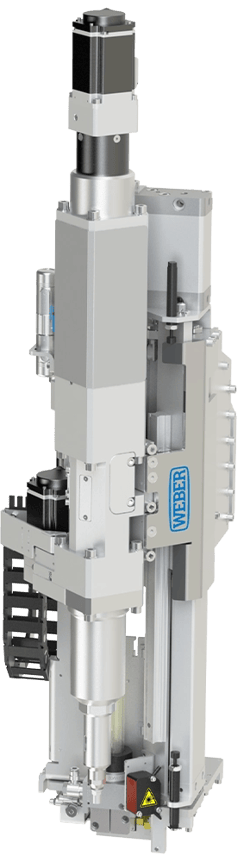

WEBER offers a system for the automated setting of blind rivet nuts and bolts that processes elements with both round and hexagonal shanks with up to 25 kN. The control and feeding technology included is optimally tailored to the process. In addition to the automated changing of the mandrel, the setting head also supports highly precise alignment of hexagonal elements and thus ensures the highest level of automation in its class. Docking-capable interfaces ensure maximum flexibility when using multiple elements or tools.

Innovative Product Features:

- Maximum process reliability through precise path and force monitoring

- Automatic change of the pulling mandrel (main wearing part)

- Precise, laser-assisted alignment of the element to the workpiece

- Automatic ejection of defective elements

Find more info in our SBM flyer.

Characteristics

- Process optimization thanks to precise alignment of the element

- IT security and control technology of the latest generation

- Dockable spindle system to process different sizes or types (nuts, bolts) alternately

- Spring-loaded pull mandrel protects the thread when screwing in and out

- Feeding the element during the setting process

- Efficient use of robot idle times