Products > Fixtured Screwdrivers

Fixtured Screwdriver SEV-C for Human Robot Collaboration

Fully collaborative automatic screwdriver, thanks to the safety concept

The connection between man and machine is a reflection of an industrial revolution that continues to this day. Machines became robots long ago. However, these days we talk about Human Robot Collaboration (HRC), which is implemented without guards. WEBER is playing a leading role here too, and with its HRC screwdriving system SEV C, the company has achieved the most complex development stage of this collaboration in accordance with ISO TS 15066. One thing always applies: Safety first. In this way, the SEV-C automatic screwdriver from WEBER combines maximum efficiency with maximum safety.

Easy job – the HRC screwdriver is perfect for lightweight robots

Collaborative robots – cobots for short – depend on consistent lightweight construction of the systems with which they are equipped. The extremely low weight of WEBER’s HRC screwdriving systems guarantees this. Pick & place screwdriving applications are implemented by the SEV-P and fully automatic screwdriving processes by the SEV-C or SEV-L screwdriving systems (including feeding). Precise, safe and weight-optimized – with innovative ideas, WEBER is already providing answers today to the screwdriving and connection technology challenges of tomorrow.

HRC capable screwdriver: built for lightweight robots (cobot)

The use of cobots is made possible by the low weight of the WEBER HRC Screwdriving Systems. Screwdriving applications can be implemented using a fully automatic SEV-C and SEV-L screwdriving system with feed. The SEV-C is the logical solution for the screwdriving and joining technology of the future, and even today it provides answers to the requirements for precision, safety and weight reduction.

Features

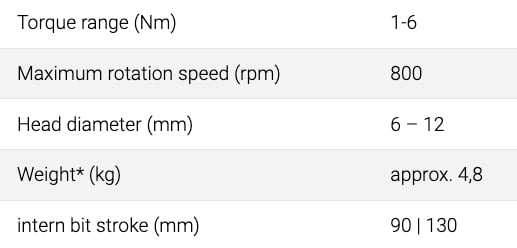

• Lightweight spindle with low weight from 4 kg

• Fully automated with ZEL feed system

• For use in cooperative and collaborative environments, thanks to safety concept

• Process: Screwdriving

• Vacuum technology for hard-to-reach locations with extremely limited access