WEBER Technology

Technical Cleanliness

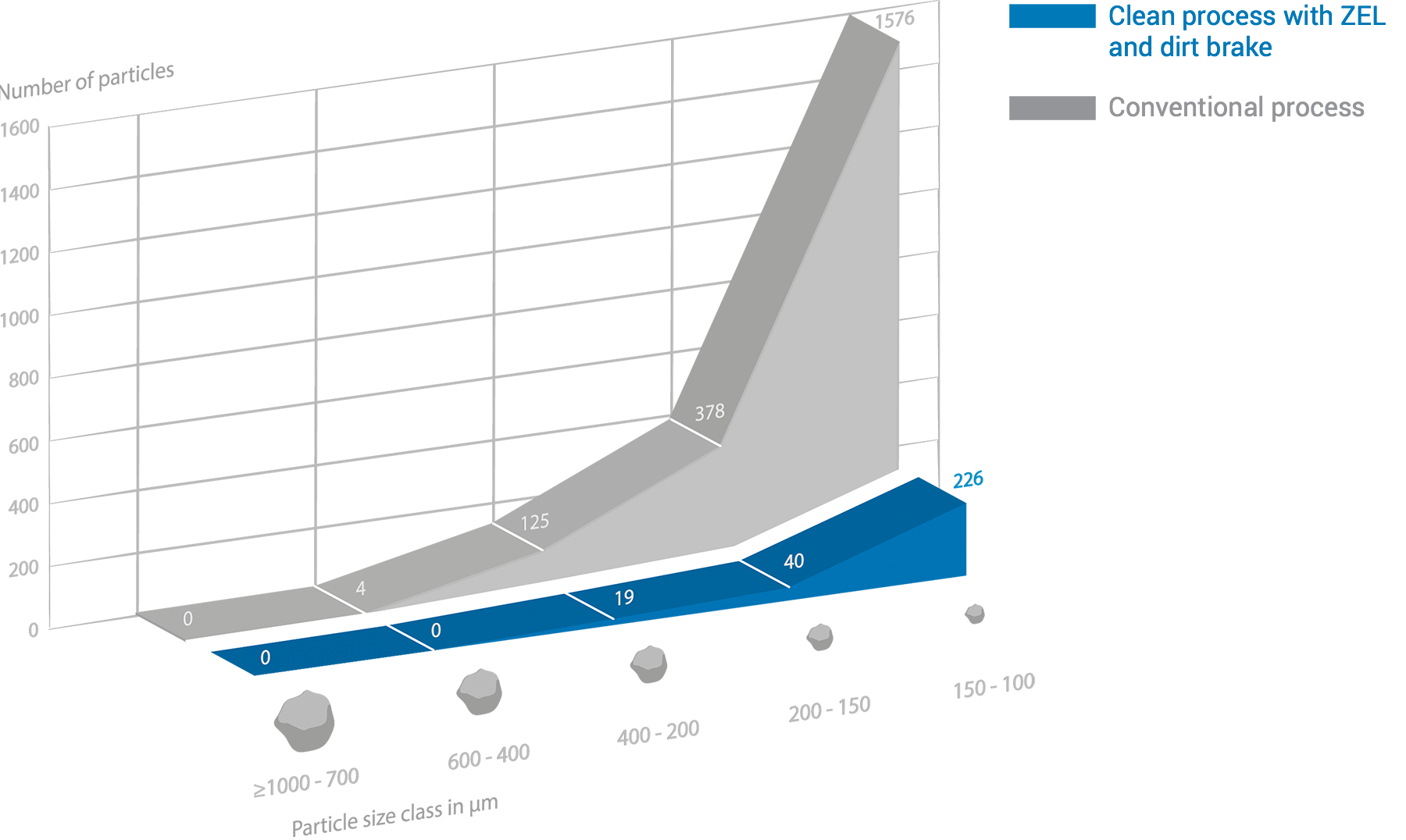

The more compact the parts and fasteners, the more susceptible they are to contamination particles. Even microscopic metal particles down to 500, 200 or even 100 microns in size may cause malfunctions. WEBER therefore relies on utmost technical cleanliness. This technology is effective: the number of contamination particles and their sizes resulting from the assembly process are demonstrably reduced. The number of particles in the size category of 100 to 150 microns decreases from 1,526 to 226, the number of particles between 150 and 200 microns decreases by 338 thanks to WEBER technology.

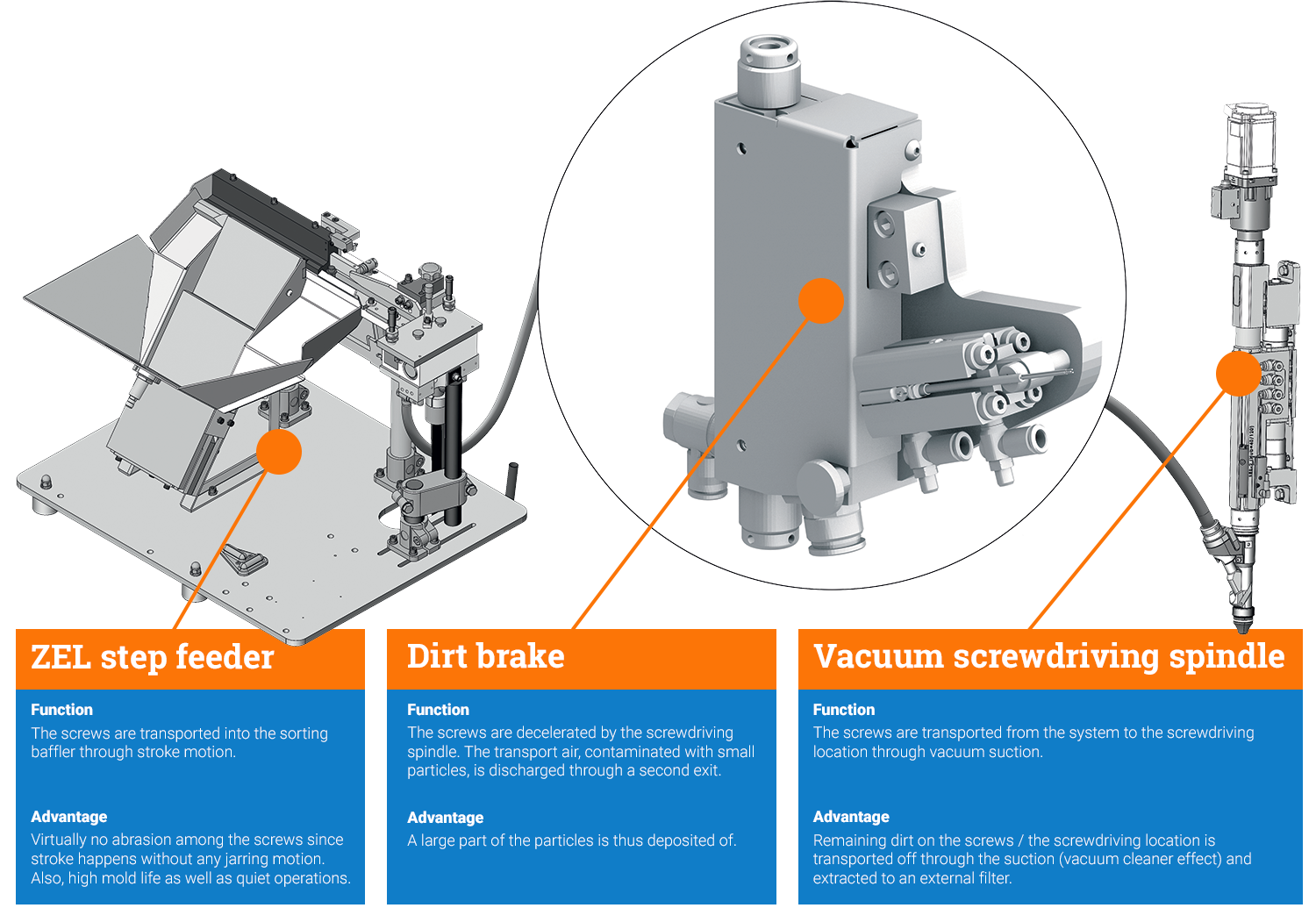

Our concept against particles

Once the parts have been unpacked for assembly, they are at risk of contamination. WEBER counters this with its long-standing know-how: The fasteners are fed to the spindle through the gentle and vibration-free step feeder ZEL, which significantly eliminates abrasion and dirt dispersion. Immediately in front of the screwdriving spindle, WEBER integrates a dirt brake that is designed in the form of a dirt turnout. Both the transport air and any surface-adhering particles are extracted at this point. The fastener overcomes the final inches to the screwdriving head through gravity. WEBER offers this technology optionally for all its screwdrivers.