Products > Fixtured Screwdriving Systems

Overview of our

FIXTURED SCREWDRIVING SYSTEMS

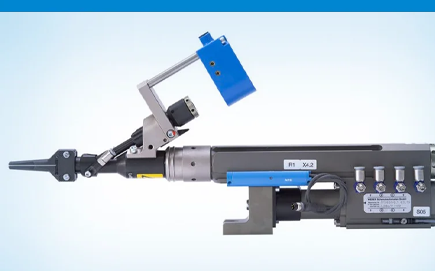

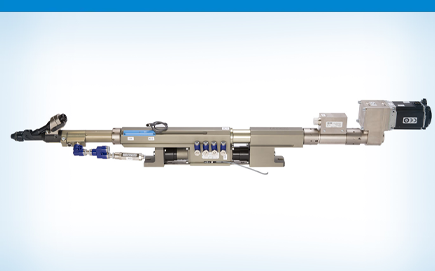

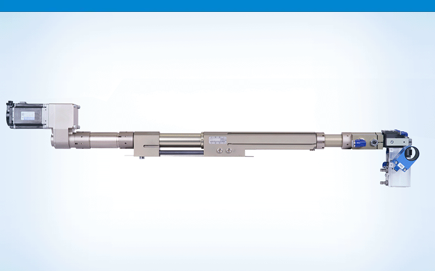

Fixtured spindles are designed for use on a mounted surface or on a robotic platform. With WEBER’s industry-leading swivel arm design, our units can feed a screw, while driving a screw at the same time.

Fixtured screwdriving technology is used if connection processes are more complex, cycle times are shorter and quality requirements are higher. WEBER’s variably configurable fixtured screwdriving spindles adapt themselves to all screwdriving cases: whether mouthpieces, stroke lengths, sensors or drive units – WEBER offers tailor-made solutions depending on the task and screwdriving process. Nevertheless, the effort to change tools on the screwdriving units remains low – thanks to the tool-free change of the screwdriving head assembly.

Frequently Asked Questions About Screwdriving Systems!

-

What is a fixtured screwdriver?

A WEBER fixtured screwdriver is a screwdriving unit or screwdriving spindle which is not held and controlled manually, but mounted on a robot, axis system or stationary fixture. In combination with a feed system, this allows different fasteners to be screwed in within short cycle times.

-

Where is fixtured screwdriving used?

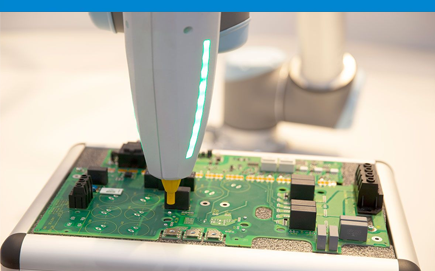

Fixtured screwdriving from WEBER is used for complex joining processes with short cycle times and high quality requirements. These fully automated screwdriving units or screwdriving spindles become economically viable from approx. 60,000 screwdriving processes per year. The automation allows the high quality requirements for the screwdriving result to be met and reproduced. Areas of application can be found on the WEBER website, in the Applications section.

-

How does a screwdriving system with an automatic screw feed system work?

On a complete screwdriving system consisting of feed unit and screwdriving unit, the screws can be filled into the feed unit as bulk goods. Different fixtures ensure that the fasteners are in the correct orientation and separate them with a separation unit – the escapement. From the escapement, one fastener at a time is blown towards the screwdriving unit through a feed hose. Depending on the screw geometry, an appropriate technology is used for transporting the screw into a mouthpiece (aligning guide). From there, the screwdriving unit can screw the fastener into the component.

-

Which elements can be processed/screwed by a screwdriving station for fastening

Screws, bolts, pins, nuts and much more. Is your element not listed here? Then please ask your local contact.

-

How fast does a screw move in the feed hose?

The speed depends in the element to be transported. A speed of 10 m/s can be used as a guide value.

-

What is the cycle time for a fully automated screwdriver with feed unit?

A cycle time of < 1 s is possible for an automated screwdriving process. This is the “start – start” time, i.e. from start of screwdriving, through feeding of the new elements until “ready” for a new screwdriving process.