3 min read

What Factors to Consider when Evaluating Automated Screwdriving Solutions

By: Tom Ash May 11, 2023 1:00:00 PM

Many benefits come with automating screw tightening. It improves consistency, leaves more time for human operators to do higher-value work, and reduces work-related injuries caused by the repetitive motions associated with manual and repetitive screwdriving. Various automated screwdriving solutions are available. What factors should you consider when evaluating automated screwdriving solutions?

Ergonomic Stress on Operators

Ergonomic Stress on Operators

Screwdriving operations have some of the highest claims for repetitive stress injuries. If your screwdriving operations still use manual processes, you are placing your operators at risk of a repetitive stress injury (RSI).

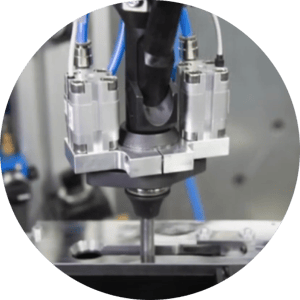

WEBER Screwdriving Solutions Offers an Internal Bit Stroke

A fully automated system will relieve the operators from the manual motion that could cause those injuries. With WEBER systems, an internal bit stroke performs that motion.

The operator pulls the trigger to advance the screwdriver bit thru the nosepiece and doesn't have to place any force to drive the screw. While the operator does have to place pressure to engage the bit, WEBER’s automated equipment reduces the amount of stress on the operator's body while driving each screw.

Automated Screwdriving Solutions by WEBER Features Ergonomic Tool Assist

WEBER also offer their Ergonomic Tool Assist feature to reduce some ergonomic concerns associated with screwdriving operations. The tool support arm – known as the HHG arm – supports the screwdriver tool during the assembly process.

WEBER’s COBOTS System Improves Safety

WEBER’s COBOTS System Improves Safety

At WEBER, we have screwdriver systems that integrate with COBOT robots, allowing the robot to move the screwdriver to the screw locations to preform the repetitive motions. It's so safe that you can have the operator work side by side with the WEBER equipment without fear of injury.

By replacing an operator with a COBOT system, you save more than just labor costs. While the cost of a robot is an excellent investment compared to hiring a human operator, the ROI overall increases because COBOTS won't need to file an RSI claim on the company's workers' compensation insurance.

System Advantages

When evaluating an automated screwdriving solution, consider the features and main advantages of the system. These advantages should include the following:

- Production volume boost - enables faster parts production

- Increase in products/parts quality - for improved process controls

- Impacts the company's bottom line - enabling scalability for maximum profitability and ROI

Throughput and Reliability

Manual screwdriving operations have several variables that are not present with automated screwdriving solutions. When you control the process, you reduce those variables and their impact on your operation.

Manual screwdriving operations have several variables that are not present with automated screwdriving solutions. When you control the process, you reduce those variables and their impact on your operation.

One variable is the number of products your equipment can produce. When demands are high, the automated screwdriving solution can assemble more with little additional preparation.

Manual operations take more time to scale for demand. Also, automated systems don't take sick leave because of illness, making them more reliable.

Automated Screwdriving Solutions

Safety is one of your top priorities, and so is the facility's bottom line. Automated screwdriving solutions not only improve facility safety but also boost throughput.

Explore the automated screwdriving solutions available at WEBER USA. Our quality systems, outstanding service, and technical know-how are why our customers buy from us.

For more information about WEBER automated screwdriving solutions, check out our Resource Library. Questions? We’re here to help.