We’ll be demonstrating our automated screwdriving and feeding solutions at this year’s premier automation showcase, Automate Show 2023!

Come See WEBER’s Automated Screwdriving and Feeding Systems in Action at Automate Show 2023 (Booth #6618)

Automate 2023 will host some of the world’s thought leaders in automation technologies. Hosted at the Huntington Place Convention Center in Detroit from May 22-25, it will be an amazing opportunity to see what’s possible in manufacturing automation today. From innovations in AI to the latest capabilities in robotics, this year’s Automate Show will have special events and keynotes from industry leaders, visionaries, and game-changing integrators.

NEW THIS YEAR!

NEW THIS YEAR!

We will be holding a beer steinholding competition each afternoon from 3:00-3:30pm. So, roll up your sleeves and test those deltoids!

HAPPY HOUR EVENT!

On Wednesday, May 24th at 3:30pm we’ll be hosting our annual happy hour at our booth where you can grab a beer, a soft Bavarian pretzel and some cool WEBER swag - like a beer koozie or magnetic bottle opener for your fridge at home.

Why You Should Visit WEBER at the Automate Show in 2023

We’ll be at Booth #6618 to show you our latest innovations in automated screwdriving and feeding technology. If you stop by, you can see our automated screwdriving, feeders, and process control solutions in action for yourself. When it comes to automated screwdriving and insertion systems, WEBER remains the industry leader with shorter cycle times, reduced product liability, and error-proofing your assembly operations.

At the show, we’ll demonstrate our key automation technologies including:

![]() Screwdriving System for Human and Robot Collaboration

Screwdriving System for Human and Robot Collaboration

Cobots have become popular in automation applications over the last decade and WEBER leads the way by combining human ingenuity with robotic efficiency. For both pick and place or completely automated systems, WEBER’s Human Robot Collaboration (HRC) solutions give you maximum flexibility without compromising on safety.

Cobots have become popular in automation applications over the last decade and WEBER leads the way by combining human ingenuity with robotic efficiency. For both pick and place or completely automated systems, WEBER’s Human Robot Collaboration (HRC) solutions give you maximum flexibility without compromising on safety.

Built in accordance with ISO TS 15066, WEBER’s range of SEV systems provides you with a lightweight, precise, and safe automated screwdriving and feeder solution.

Error Proofing with 3D Process Control

Error Proofing with 3D Process Control

Our C30 Process Controller measures the torque, angle, and depth while driving each screw. This data allows you to error-proof your process by stopping the screwdriver if you didn’t drive the screw to the required specification. You can automate your data collection, keep logs of each driving operation, and document rolling torques for reduced product liability using the C30S Process Controller.

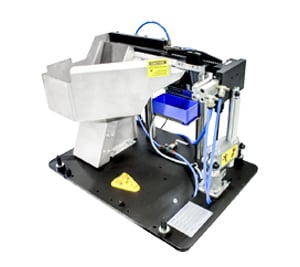

Automated Step Feeder for Reduced Cycle Times

Automated Step Feeder for Reduced Cycle Times

The ZEL step feeder can feed screws with cycle rates as low as 0.8 seconds. With a low vibration outlet rail, you can feed screws gently into the system and ensure each arrives with its surface coating in place when driving into sensitive parts. You can come see this revolutionary system with integrated sensors, reduced noise emissions, and automated process control in action at our booth.

The ZEL step feeder can feed screws with cycle rates as low as 0.8 seconds. With a low vibration outlet rail, you can feed screws gently into the system and ensure each arrives with its surface coating in place when driving into sensitive parts. You can come see this revolutionary system with integrated sensors, reduced noise emissions, and automated process control in action at our booth.

Robotic Cell with SEV-P Pick and Drive

Robotic Cell with SEV-P Pick and Drive

The SEV-P is a tightening screwdriver without automatic feed system, designed for pick & place applications. WEBER vacuum technology allows the fastener to be fetched, guided reliably to the fastening point and fastened with the screwdriving spindle. Thanks to the extremely compact design, the 6 Nm spindle weighs just 1.5 kg. The screwdriver has a flange as per ISO 9409-1-50-4-M6 and is therefore suitable for adaptation to a variety of different lightweight robots.

Handheld Screwdrivers - DC Electric Screwdriver HSE

Handheld Screwdrivers - DC Electric Screwdriver HSE

This device allows the use of any DC electric or DC torque and angle system to be fitted to the back of this hand held device. The fast self advancing automatic bit stroke device allows the fastest installation in the business. When the start button on the handpiece is depressed the self advancing bit starts to move forward out of the jaws to expose the bit and fastener while simultaneously starting the DC tools rotation. As the bit and fastener become exposed this allows the operator much greater visibility and creates a greater clearance from the parts automatically.

This device allows the use of any DC electric or DC torque and angle system to be fitted to the back of this hand held device. The fast self advancing automatic bit stroke device allows the fastest installation in the business. When the start button on the handpiece is depressed the self advancing bit starts to move forward out of the jaws to expose the bit and fastener while simultaneously starting the DC tools rotation. As the bit and fastener become exposed this allows the operator much greater visibility and creates a greater clearance from the parts automatically.

After completion of the cycle, the next screw is already loaded into the handpiece and the system goes into a Bitlock position which prevents the fastener falling back up inside the system and holding the tip positively exposed for good operator targeting. The ease of use and extremely rugged construction can only add to the legendary Weber reputation of reliability.

SEM Automatic Feed and Drive of Hex Nuts

SEM Automatic Feed and Drive of Hex Nuts

For nuts and head-heavy fasteners, this solution is perfect! The SEM is suitable for use with nuts, flanges and special nuts. This model use vacuum technology to reliably supply the fasteners and automatic feed systems. Another compelling feature of the fixtured screwdrivers SEM a is it's use of a reversing gear module with a compact design.

Discover WEBER’s Automated Screwdriving and Feeding Systems at the Automate Show 2023

We look forward to seeing you at this year’s Automate Show where we can discuss your specific requirements, share a few drinks, and show you what endless possibilities there are using our automated screwdriving and feeding systems.

If you can’t wait until the Automate Show in May, feel free to reach out to us today.