5 min read

Why Feeding the Washer (Not the Hex Bolt) Changes Everything

By: Michael Rabasco Sep 11, 2025 9:30:00 AM

I recently visited a client of ours from Tennessee to check in on a new project that they are working on, and we were able to lend a hand by providing some of our solutions. In the video, I walk through the solution and point out some of the ways that WEBER found some unique solutions to solve their problems.

Check out this video or read the transcript below:

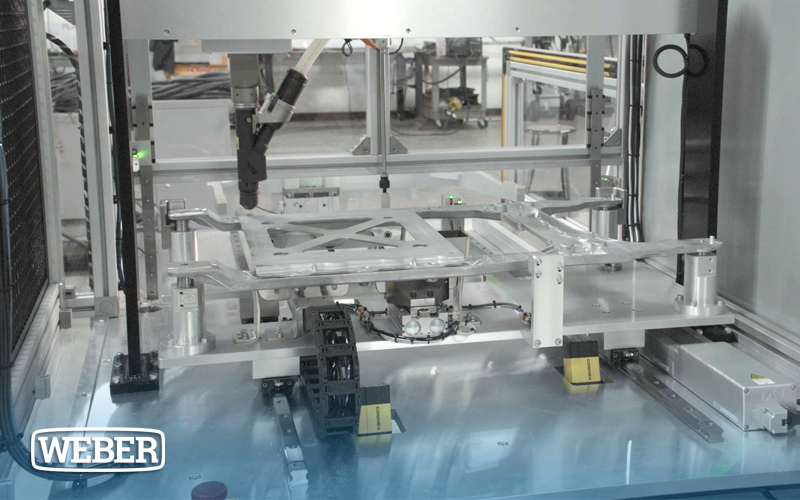

Hi, Mike Rabasco here from WEBER Screwdriving Systems. Today, we are at a local machine builder in Tennessee, and I’m going to show you how we get an X-bracket attached to an H-bracket. So the challenge today is to use six of these screws, these bolts, hex head bolts with a loose washer, to assemble these two pieces together to a torque of 22 newton meters.

Let’s start out with the feeder. As I mentioned, these are hex head bolts. The interesting thing about these bolts, and we are seeing this more and more, is that it has a loose washer. You see this washer, even though it’s contained on the shank of the screw, it can kind of ride around here loose and sometimes they actually get stuck on that first thread which makes it a little difficult to feed sometimes because the head heights can vary so much.

At WEBER, we have taken a little bit of a different approach. I can tell the people that I deal with in my shop, “don't feed the bolt, feed the washer.” That’s what we are going to show you here. This is WEBER's ZEL 360 feeder. We make a lot of step feeders and they are super reliable.

At WEBER, we have taken a little bit of a different approach. I can tell the people that I deal with in my shop, “don't feed the bolt, feed the washer.” That’s what we are going to show you here. This is WEBER's ZEL 360 feeder. We make a lot of step feeders and they are super reliable.

One of the unique things about WEBER Screwdriving Systems is that every single feeder that we build is completely blueprinted. What that means is that every single component on here, whether it’s the escape or the track tooling or the sorting area, everything is machined, it’s made out of tool seal, it's hard, and it gets a part number, which means there isn't a piece on this feed system that you can’t order as a spare part. Everything is replaceable.

Containing the washer, not the head of the bolt

One of the interesting things about this particular feeder, as I mentioned, the loose washer on here, is that we want to actually contain the washer and not so much the head of the bolt. So, in doing that, what we did here was we developed tooling which allows us to guide the washer rather than the head of the bolt.

In other words the bolt can kind of free spin, and it can move up and down inside the tooling here, and what we are actually feeding or what we are actually capturing is the washer. The washer seems to be behaving against one another. It's the head that seems to vary in head height, as the shank of the screw can ride up and down inside this washer. We singulate these one at a time through the feeder, blow them through a piece of feed tube, which in this case is quite far, and we are going to blow these over to a device we call a feed brake.

Another challenge with this application is getting the screw from the feed system up this long stretch of feed tube and down into the driver without having the fastener have so much velocity on it when it hits the driver that it starts to wear the head tooling out. So, one of the ways we do this is we implemented what we call a feed break. This feed break uses a couple of different methods to slow the fastener down.

Feed Brake

The first thing you will see is a ring sensor up top, which tells us if the screw has traveled through the tube to the highest point in the arch. When we see that sensor, we shut the air off so we start to coast a little bit, and what will happen is that the screw will get trapped in that feed brake, as you will see in the video, and what we do is we actually do exactly that.

We brake the screw. We stop it from moving, once we understand the screw is in the break and it's secure and it’s stopped we can release the screw gently into the feed head. What that does is it allows us to feed while we drive, we can be driving a screw and feeding the next one.

It also means that the velocity of the fastener going into the head is going at a reasonable speed so we don't either blow it through the jaws or we wear the feeding tooling out at the head. Once a screw is delivered through the feed tube past the break the screw is going to end up in a set of jaws here. This is the feed head tooling. What will happen is this part will move underneath the driver, the driver will move in this direction, it will go up and down, this direction will be on a servo, and you will see how this works here in a second.

Analog Depth Sensor

Another interesting thing about the screwdriving spindle itself is that we have what we call an analog depth sensor. The analog depth sensor measures where the bit is in space at all times. It’s one thing to have a tight screw; it's another thing to have it tight and in the right position. What this sensor does is it allows us to monitor where the screw is positionally in the part.

Another interesting thing about the screwdriving spindle itself is that we have what we call an analog depth sensor. The analog depth sensor measures where the bit is in space at all times. It’s one thing to have a tight screw; it's another thing to have it tight and in the right position. What this sensor does is it allows us to monitor where the screw is positionally in the part.

If you have a screw that seizes up too early, it doesn't go all the way in, but it is at the right torque and at the right angle, we are going to fail it because this sensor didn't see enough travel. Another feature is the quick bit change. What we do to change a bit of this is very easy. We pull this ring down, release the head.

If you need a little more clearance, you can pinch these two little levers here, pull the feed tube right out, drop this down, pull this ring out, and that's it. That's your bit. It goes in just as easy. Back in, pull this down, all the way up, take the feed tube, slide the feed tube back into the swivel arm bracket here, reinstall, and you are back in business that quickly. Literally, that takes 30 seconds.