4 min read

3 Major Advantages of Using Step Feeders in Your Screwdriving System

By: Michael Rabasco Feb 10, 2022 11:00:00 AM

Choosing the right feeder for your fastener can be tricky, but it doesn’t have to be. If you are evaluating the latest, most efficient technology that supports automatic screw feeders, then the step feeder is the place to start.

You can use screw feeder machinery on more than just screws. With a variety of mechanical fastening methods, you can accommodate feeding large bolts, nuts, micro screws, double-ended screws, valve cores, rubber balls, clips, fasteners, and more.

You can use screw feeder machinery on more than just screws. With a variety of mechanical fastening methods, you can accommodate feeding large bolts, nuts, micro screws, double-ended screws, valve cores, rubber balls, clips, fasteners, and more.

Bowl feeders do serve a valuable function. Typically in the industry, we hear complaints about noise and heavy vibration. We’ve found that polycast bowls, which have a hard durometer outer shell, are less noisy compared to the more common stainless-steel bowl. Despite this convenience, step feeders are the go-to solution if you want the most efficient screwdriving and feeding system.

3 Major Advantages to Using Step Feeders

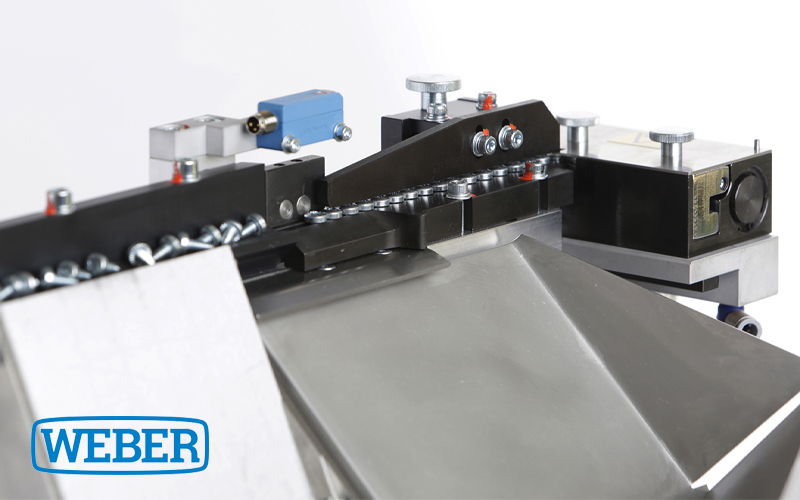

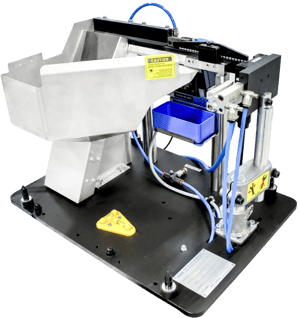

The step feeder functions with steps that go up and down, which lift screws onto the vibratory inline.

When screws or small parts are lifted to an inline, the recycling of those parts is very low. The step feeder is more efficient because it offers higher efficiency and faster cycle rates.

There are a few disadvantages to using step feeders. They are slightly more expensive, and they don’t handle razor-sharp screws – such as those used in wood products and composite materials – as well as the bowl feeders. However, for most applications our clients tend to prefer our step feeders for these reasons:

Handle Fasteners and Small Parts More Gently

Handle Fasteners and Small Parts More Gently

The methodology of feeding screws into a step feeder involves the screws sitting static in the pan rather than vibrating against the other parts, as they would in a bowl feeder. This process immediately reduces wear on parts to next to nothing.

Lower Noise Levels: Step Feeder Technology is Quieter

Lower Noise Levels: Step Feeder Technology is Quieter

The decibel and vibration level of step feeders is much lower than that of the average bowl feeder, which overall in the industry tends to be very loud. In fact, step feeders are whisper-quiet.

More Room for Enhancements

More Room for Enhancements

The step feeder has more room for camera systems and integrated sensors that assist with essential part inspections.

For example, camera technology and vision systems can determine if screws are the correct color and fit for the product. If not, the screws can be diverted to a non-confirming receptacle.

Fastener length detection built into step feeders helps to prevent the wrong screws from getting on the line and potentially destroying machine parts. WEBER employs this depth sensor technology to ensure that only correct parts are added to the line.

What are the Most Common Issues with Feeding Solutions?

Typical issues with feeding solutions in the industry include:

- Frequent jamming: Jamming is when the feeder stops working, which results in employee and production downtime to resolve the issue.

- Damaged parts: Some feeding solutions fail to protect parts from damage. When you put fasteners in a bowl feeder, they bounce around and vibrate together. If the parts are painted, the paint is likely to be shaken or chipped off, compromising the finish.

The good news is, this isn’t the case when working with WEBER. Through error proofing, process, and product reliability, WEBER employs every bit of technology possible to ensure that the feeding process is completed properly, with minimal issues.

WEBER automatic screwdriving and feeding technology, in conjunction with process control, reduces cycle time and overall improves ROI on the line.

Beat the Standard Industry Solution for Fastener and Small Part Feeding

Hand crafted parts are impossible to duplicate. With feeding in general, WEBER stands alone – because whenever we develop any technology or solution, it is blueprinted and documented so that parts can be easily adjusted or replaced, just by referring to the manual to identify the missing parts.

While smaller companies may not have the flexibility for industrial solutions, WEBER can make design adjustments to new step feeder technology to create standards-based feeders to your market specifications.

Check out WEBER screw feeding systems and other products today.