3 min read

Screwdriving Technology Solutions for an Obstructed Access Point

By: Michael Rabasco Sep 5, 2022 8:30:00 AM

When you have challenging assemblies with obstructed access points, the choice of screwdriving technology can make or break your process, literally. Product liability arises when you cannot tell if you’ve seated the screw properly or achieved the required clamp loads after the driving operation. Overcoming obstruction points under these conditions is still possible with WEBER’s vacuum-fixtured screwdriving system.

The modular design of our screwdriving technologies enables us to customize a system that can solve even the most complex assembly operations. To help you improve your process, let’s look at how our vacuum screwdriving technologies can help you overcome obstructed access points in your assemblies.

Overcoming Challenges with Obstructed Access Points with WEBER Screwdriving Technologies

A variety of factors will dictate the overall design of your vacuum screwdriving system. At WEBER, we work with manufacturers that have to ensure each screw reaches the right depth, torque, and angle for assemblies with obstructed access points and tight clearances.

To get started, our team will need insights into your process parameters including:

- The CAD design of the part and the fastener technique currently proposed or deployed

- The tolerance model of the part and the screw to identify the available league of limits

- The precise geometry (and variances) of the screws you’ll use in the assembly

- The material selection of the part that could cause shrinkage or warpage

This information allows us to recommend a system design that not only overcomes the obstructed access point but can help you limit product liability while error-proofing the screwdriving operation.

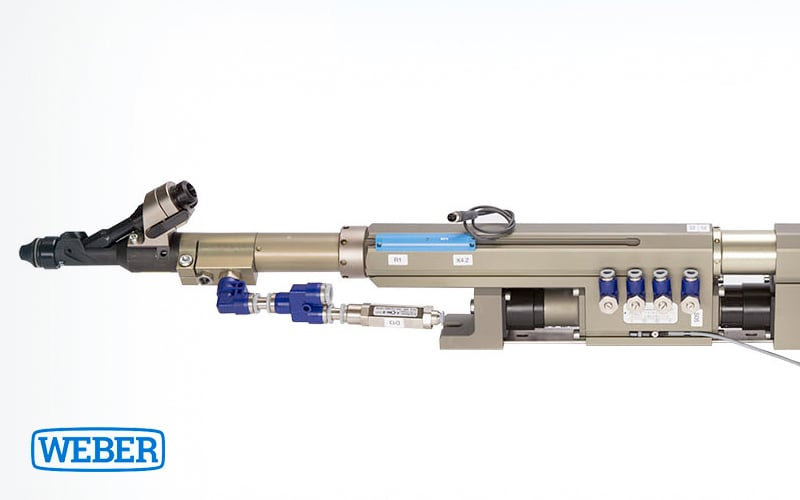

WEBER Fixtured Vacuum Screwdriving Technologies

Combined with our C30 process controllers, the WEBER SEV fixtured screwdriving system uses a vacuum nosepiece and bit to hold the screw in place before starting the driving operation. The stroke will travel until it reaches the required depth before receiving a start signal from your PLC. Additionally, the C30 controller will measure the angle, torque, and depth of the screw to reduce product quality issues and alert you of a defective part before you send it out to your customers.

Combined with our C30 process controllers, the WEBER SEV fixtured screwdriving system uses a vacuum nosepiece and bit to hold the screw in place before starting the driving operation. The stroke will travel until it reaches the required depth before receiving a start signal from your PLC. Additionally, the C30 controller will measure the angle, torque, and depth of the screw to reduce product quality issues and alert you of a defective part before you send it out to your customers.

The key benefits of the SEV fixtured vacuum system are:

- Highly customizable with modular design and configurable to your exact specifications

- Able to accommodate electric and pneumatic motor drives for maximum flexibility

- Capable of driving at any angle including inverted assembly applications

- Ideal for overcoming obstructed access points and hard-to-reach, deep recesses

Trust WEBER to Help You Overcome Obstructed Access Points in Your Screwdriving Operations

WEBER continues to develop innovative screwdriving technologies that help manufacturers overcome daily challenges. With the ability to see each driving operation in 3D and reach those access points that others can’t, our systems reduce product liability issues, increase cycle times, and automate screwdriving operations for maximum throughput.

If you want to discuss your screwdriving applications that need to overcome obstructed access points with an expert, contact WEBER here.