1 min read

Integrating an Application with High-Speed Screwdriving Requirements (50-75 cycles per minute)

By: Carl Kulling Mar 15, 2022 10:45:00 AM

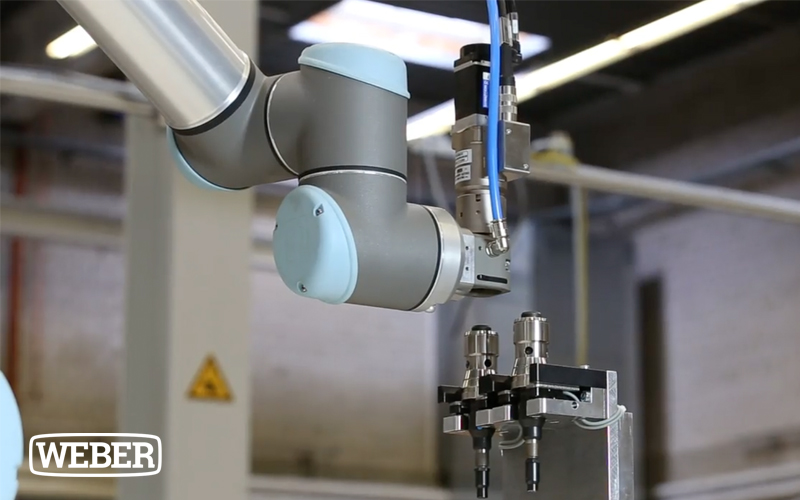

Screwdriving production automation plays a crucial role across industries, from automotive to consumer products and medical equipment. To meet the demand for production requiring a high rate of cycles per minute, companies need to integrate their applications with high speed tools. At WEBER, our goal is to make automation easy - and in this video we’ll explain how automated screwdriving can increase cycle time while increasing accuracy at the same time!

Fixtured screwdriving systems are fully automated units, and they allow the machine to perform the entire cycle of installing a screw without stopping - perfect for those looking for a system capable of high volume output.

These systems are excellent for those high-volume applications which require a large number of cycles per minute. In fact, WEBER’s fixtured screwdriving solutions are designed to operate at a full 50-75 cycles per minute. The high-speed capabilities of the fixtured screwdriving solutions, such as the SEB/SER fixtured systems, are ideal for those companies which require a high production rate on their products. These systems operate in a more efficient, cost-effective manner.

Another benefit of screwdriving production automation includes the control systems, such as the WEBER C30s Controller.

The C30s is designed to solve complex screwdriving applications, allowing you to count cycles, collect screw installation data of assembled parts along with on-board analysis tools to ensure quality and uptime.

It also helps you monitor your fastening application and make changes to the installation specifications such as torque, angle, and depth – enabling you to perform your most critical tasks with just a few clicks of the mouse.

Curious how you can integrate a fixtured screwdriving system into your assembly line?

The WEBER team can help. We’re here to make automation easy!