3 min read

Tips for Thermal Adhesive Bonding Automation for Lightweight Aviation Applications

By: Tom Ash Dec 1, 2022 9:15:00 AM

People within the automotive and aerospace industry understand how essential precision bonding is and how vital each component can be. The lightweight material requires a thermal adhesive bonding process for automating lightweight aviation assembly applications.

Here are a few tips for automating a bonding process for a lightweight aviation application. First, let's go over what a thermal adhesive bond is and what materials it bonds together.

What is a Thermal Adhesive Bond?

What is a Thermal Adhesive Bond?

Thermal adhesive bond uses a thermal setting system (TSS) that allows the placement of a plastic boss in a sandwich structure consisting of a honeycomb or foam core with outer layers of fiber-reinforced plastic (e.g., CRP or GRP).

During TSS assembly, the plastic components are melted, creating a thermal adhesive bond. The process places the plastic covers with or without pilot holes. Furthermore, you can implement it with robotic assistance.

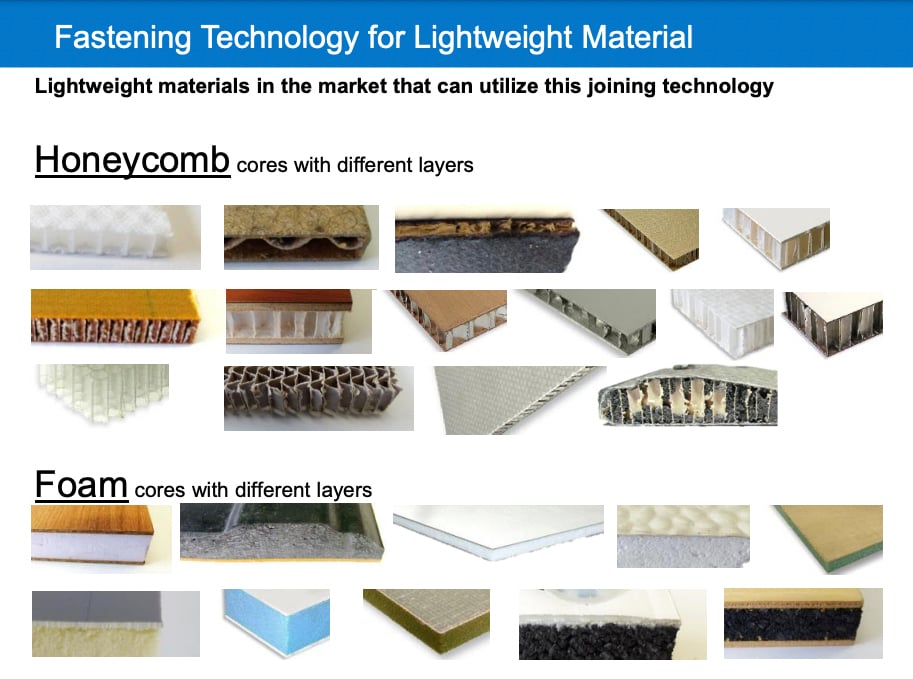

The WEBER TSS Solution delivers fastening and joining technology for lightweight materials, such as:

- Honeycomb cores

- Foam cores

- EPP foam materials

- Carbon fiber panels

Apply the TSS process as a closed setting facility in a cell or a robot-assisted system. Use the domes directly as robust threaded inserts or simply as fasteners for self-tapping screws. The entire process is freely configurable.

Creative Tips for Automating Joining Operation for Lightweight Applications

When choosing a robot for automating your Joining operation, you need to understand that human operators will be slightly faster than robotic ones. However, while human operators are quicker, they are also less consistent and prone to errors.

That means you will need to:

Choose a Robot

Consider the bigger picture at hand. Automating your processes may or may not improve your cycle times for you, but regardless you can still increase output and produce more without the need for human resources. That way you can keep personnel available for essential manual tasks.

Master Your Process

Make sure that the system can easily align the assembled parts. Also, ensure the fastening process is simple. You do not want to start by adding additional compounds.

Automation Made Easy with WEBER USA

Automation Made Easy with WEBER USA

At WEBER, we make automation easy. When you are working with lightweight aviation and automotive parts, you need the precision of WEBER's thermal adhesive bond technology.

Our featured joining method to fasten components of lightweight materials ensures bonding as long as one of the materials has a fiber component. The depth measuring tool of our TSS Solution will guarantee your bonding screw is the correct depth every time.

Check out WEBER Thermal Setting Systems and our other products today.