Products > Feeding Systems

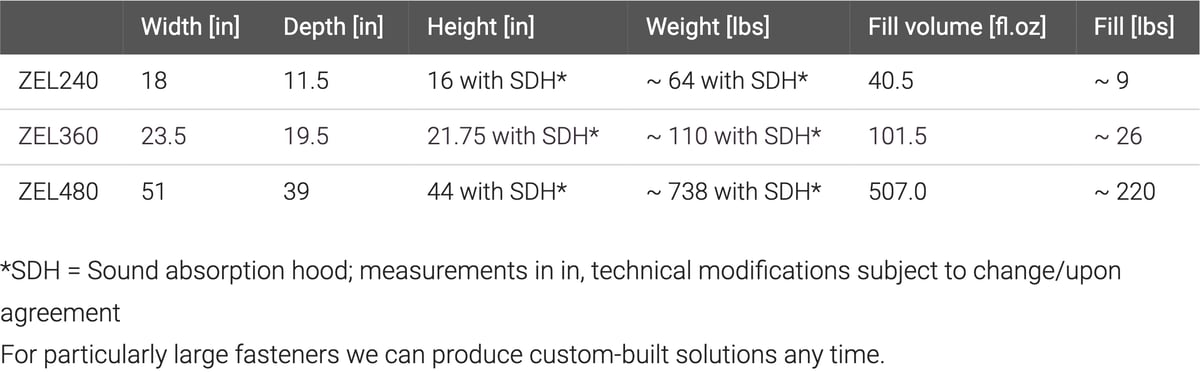

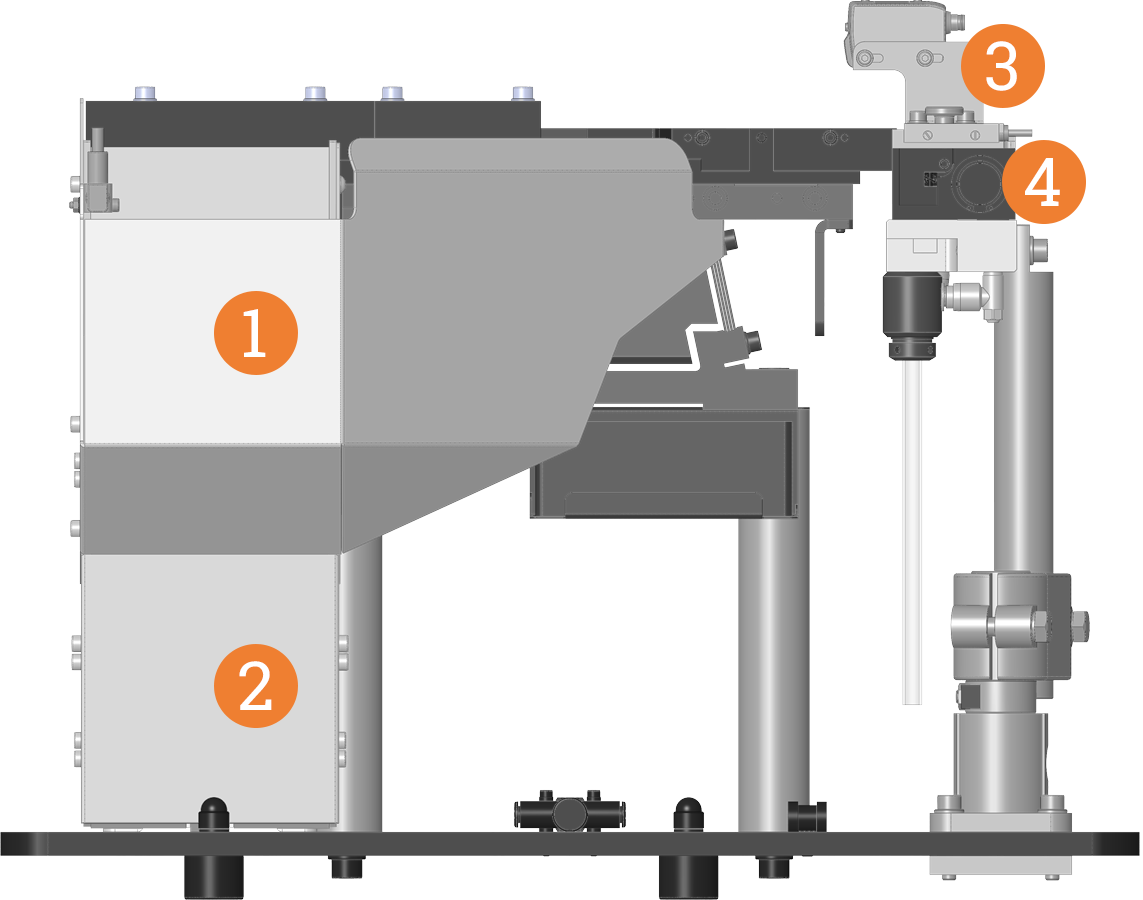

Step feeder ZEL

Low noise emissions

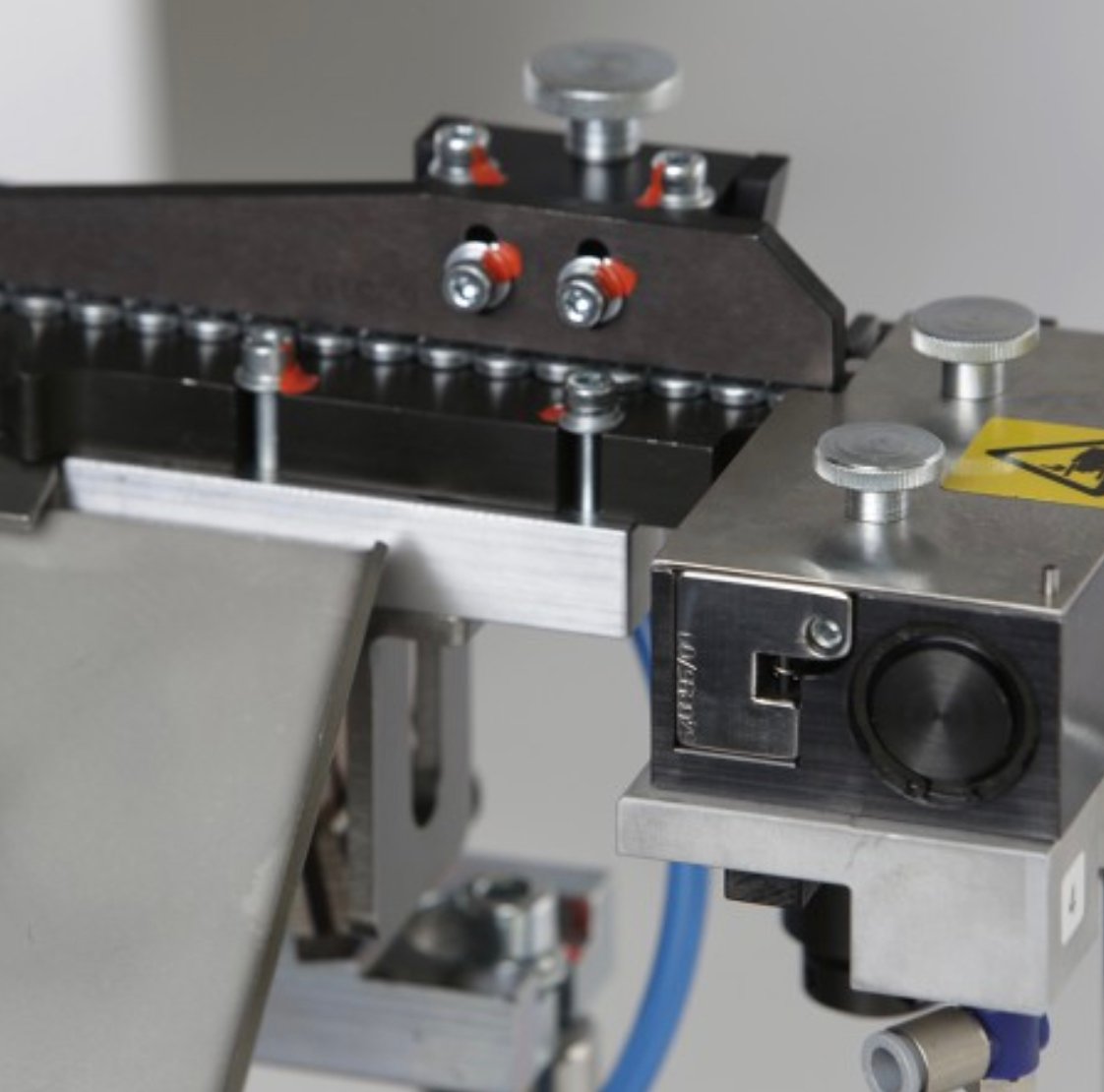

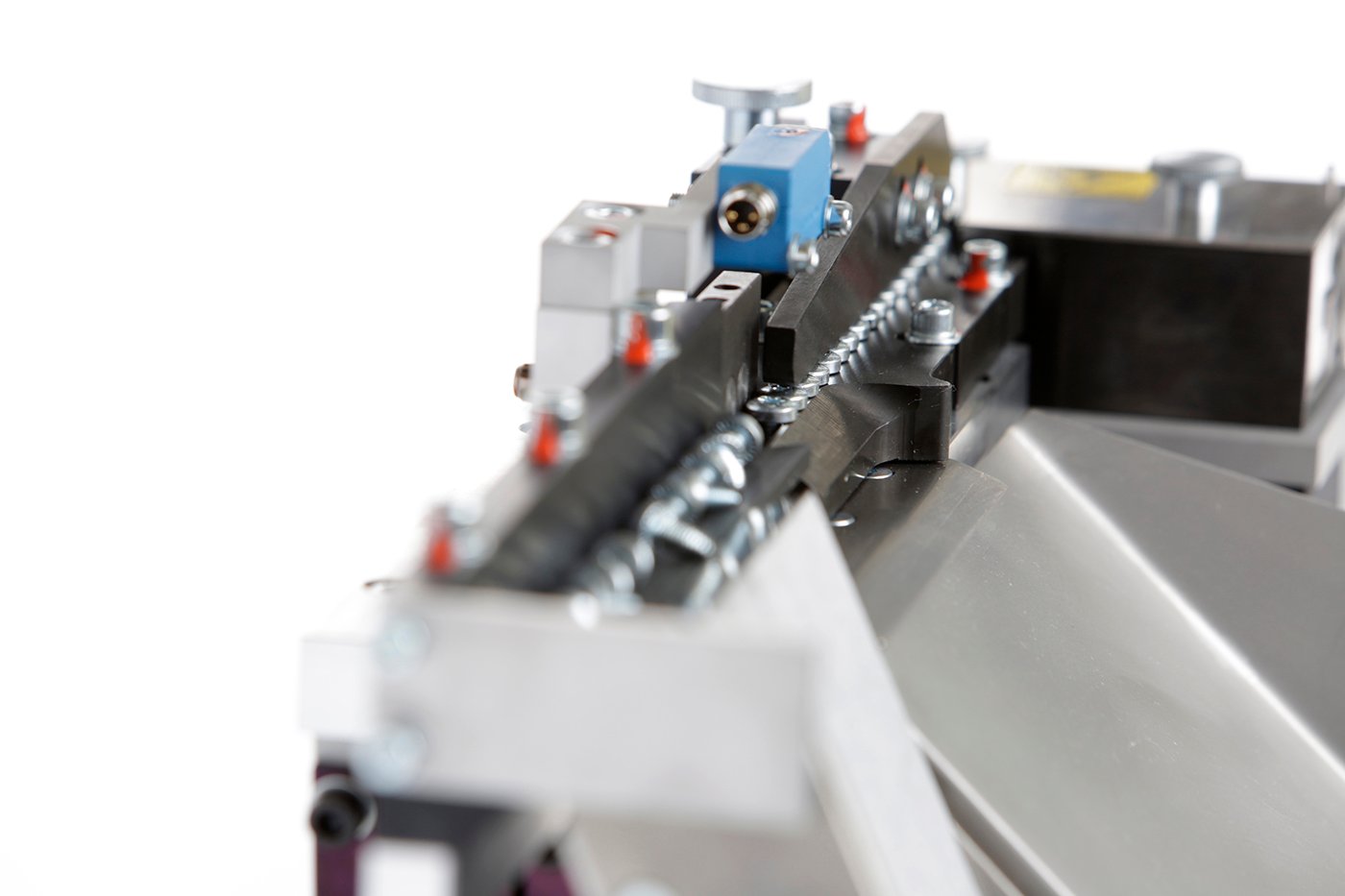

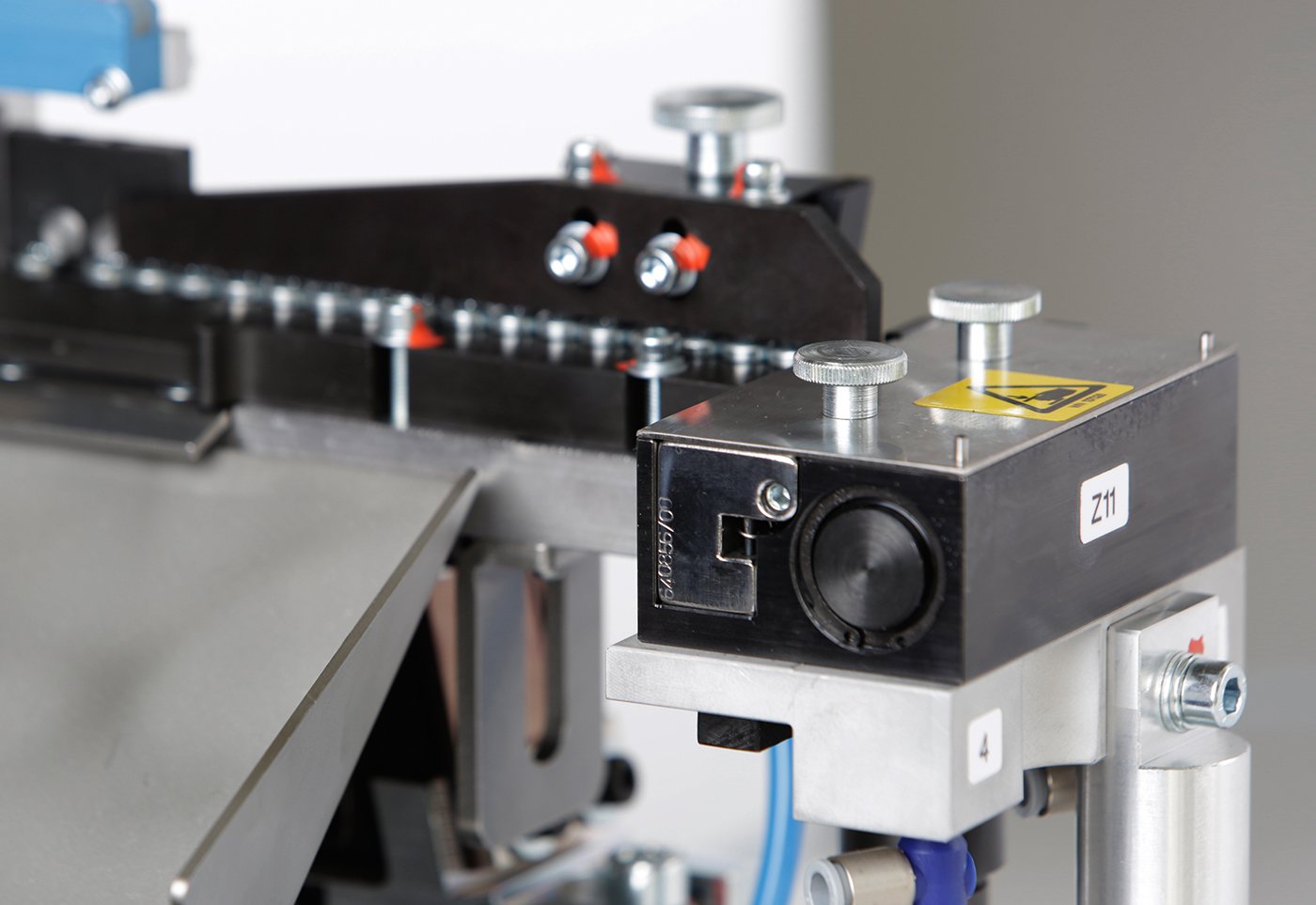

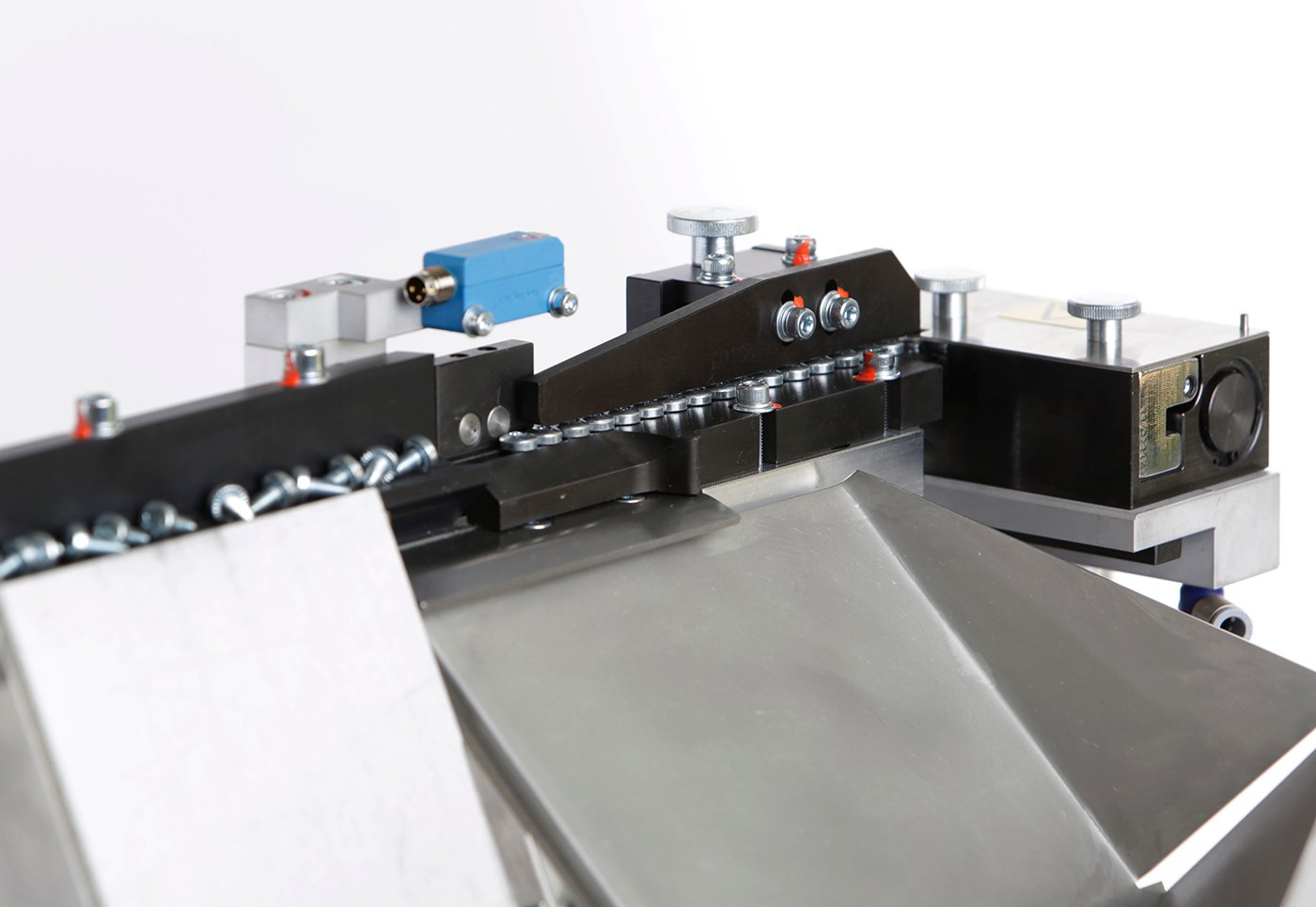

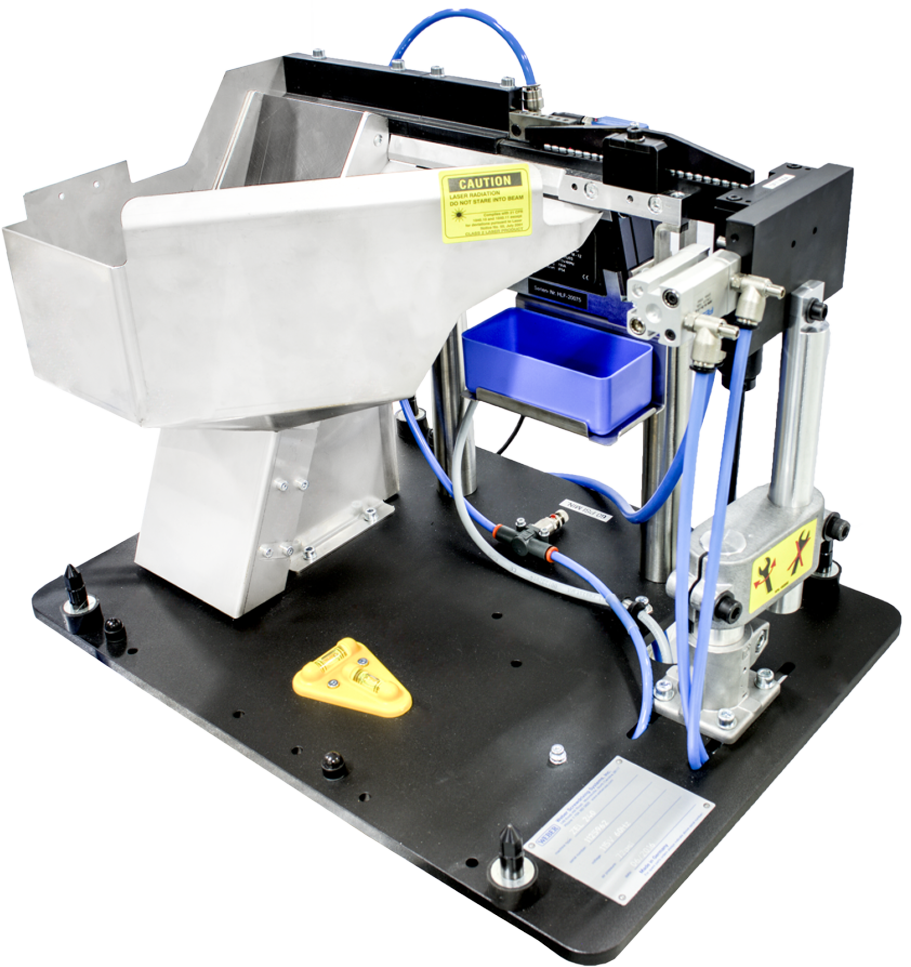

The ZEL feeds screws, nuts and pins and is gentle on the material. The system allows cycle rates as low as 0.8 seconds. A low-vibration outlet rail, which minimizes vibrations, enables processing of surface-coated and sensitive parts. This is a very important aspect particularly in terms of the requirements of technical cleanliness. Integrated sensors ensure high process reliability. The measures to reduce noise emissions are designed for noise protection at the workplace.

Low susceptibility to soiling

The reservoir for fasteners is made of stainless steel – the integrated slider of hardened tool steel or plastic. These surface characteristics reduce abrasion and prevent soiling. A belt bunker can be installed as an option.

Features

• Gentle method of conveying

• Very low noise emissions

• Fast feeding

• Low abrasion of fasteners

• Stainless steel pans

• Optional cover

• Ideal for clean screw technologies

• Hardened tool steel is used on all critical areas (escapement, tracks, sorting areas)