Products > Control Systems

Process controller C50S

Tailored individuality

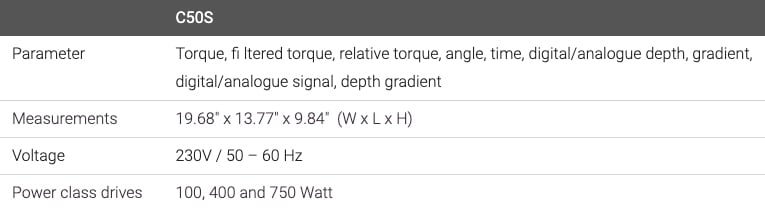

The C50S process control is used for individually configurable screwdriving processes. There are 255 selectable screwdriving programs available – custom programs can be completed via an open interface. Networking is realized via Ethernet with TCP/IP protocol. The sequences are visualized on an optional Touch-Panel or a Windows computer.

For demanding applications

Detailed information about the screwdriving curves and characteristics can be output with the controller C50S. All relevant process signals are represented on any abscissae. Options for system diagnosis, a logbook, and a backup and help function are also available.

Features

• 255 programs

• Five results selectable from any stage

• Statistical functions for process quality assessment

• Advanced screwdriving methods: gradient screwdriving (torque, depth), relative torque and M360 each with up to 25 screw stages

• Digital and analogue depth measurement to optimize screwdriving processes

• Process parameters set via customer interface

• Advanced process analysis and diagnostics: last 1,000 curves stored in the control and up to 10 curves superimposed in visualizations

• Visualization on any PC or optional WEBER touch monitor

• Optional redundant measuring system VDI 2862, Class A

• Digital I/O, Profibus, ProfiNet and Ethernet IP