Screwdriving Technology for the

Medical Devices Industry

Screwdriving Technology for Medical Devices

From microscope to X-ray machine – from simple surgical instruments to the operating table: medical devices are as varied as they are crucial. Almost all of these devices are joined by some means of screw connections. This also applies to prostheses or other medical aids.

The medical product law dictates maximum cleanliness up to sterility of the devices. For connection technology, this means a maximum degree of technical purity during the connection process. Material properties and high precision of the connections are additionally of key importance.

WEBER sets standards in the realization of maximum technical cleanliness in the connection process and meets the high standards of the industry. This commitment to quality goes hand in hand with the guarantee of maximum process reliability.

QUESTIONS? LET'S TALK!

CASE STUDY

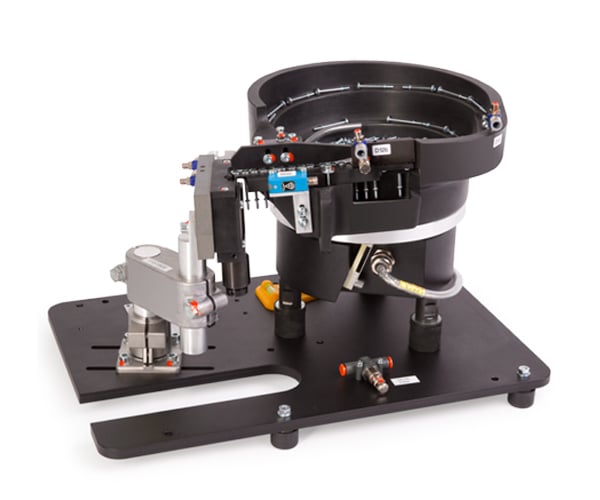

Multi-Screw Feeder

Weber USA offers a new level in flexibility and speed of operation with our stepfeeding solutions. This stepfeeder based device will accommodate many variations in length in the same track tooling. Only when the fastener diameter changed, required a “tools free” swap out tooling get utilized. The system was required as a high speed presenter for robotic pick-up, but equally could be used with the highly reliable Weber escapement for blowfeeding.